Tinned copper stripchinhu chesimbi chine mupendero werata pamusoro pemutsetse wemhangura. Nzira yekugadzira tambo yemhangura yakakamurwa kuita matanho matatu: pre-kurapa, tin plating uye post-kurapa.

Zvinoenderana neakasiyana tin plating nzira, inogona kukamurwa kuita electroplating uye inopisa-dip plating. Pane misiyano pakati pe electroplated tinned copper strip uye inopisa-diptinned copper stripmuzvinhu zvakawanda.

I. Process musimboti

1) Electroplating tinning: Inoshandisa musimboti we electrolysis kushandisa iyocopper stripse cathode uye tini seanode. Mumushonga we electroplating une tin ions, ma tin ions anoderedzwa uye anoiswa pamusoro pemupendero wemhangura kuti aite tin-plated layer kuburikidza nekuita kwekunanga ikozvino.

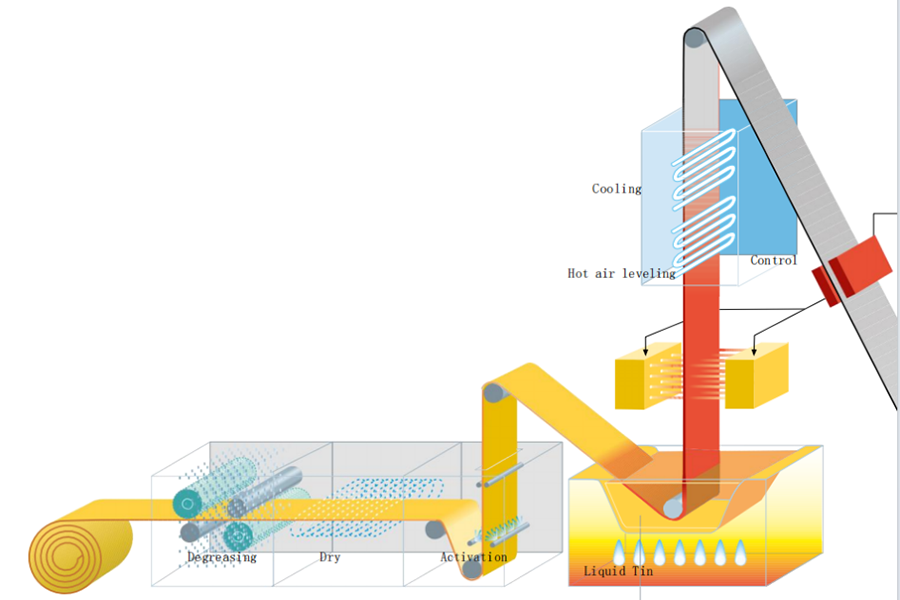

2) Kupisa-dip tinning: Iko kunyudza iyocopper stripmumvura yerata yakanyungudutswa. Pasi pehumwe tembiricha nenguva, mvura yerata inopindirana nenyama nekemikari nepamusoro pemutsetse wemhangura kuti igadzire tin layer pamusoro pemutsetse wemhangura.

II. Coating maitiro:

1) Coating kufanana

A) Electroplating tinning: Kupfeka kwakafanana kwakanaka, uye kunogona kugadzira yunifomu uye yakatetepa tinning layer pamusoro pecopper strip. Kunyanya kune mitsetse yemhangura ine maumbirwo akaoma uye isina kuenzana nzvimbo, inogona zvakare kuvhara zvakanaka, iyo inokodzera mamiriro ekushandisa ane zvakakwirira zvinodiwa zvekupfekedza kufanana.

B) Kupisa-dip tinning: Kupfeka kwakafanana kwakashata, uye kusaenzana kwekukora kunogona kuitika pamakona uye kumucheto kwe.copper strip. Nekudaro, kune dzimwe nguva apo izvo zvinodikanwa zvekupfeka zvakafanana hazvina kunyanya kuomarara, kukanganisa kudiki.

2) Coating ukobvu:

A) Electroplating tinning: Ukobvu hwekuputira hutete, kazhinji pakati pema microns mashoma uye makumi emamicrons, uye hunogona kunyatso kudzora zvinoenderana nezvinodiwa chaizvo.

B) Kupisa-dip tinning: Hukobvu hwekuputira hunowanzo kukora, kazhinji pakati pemakumi emamicrons nemazana emamicrons, ayo anogona kupa zvirinani kusaita ngura uye kusapfeka kwemitsetse yemhangura, asi inogona kunge isina kukodzera kune mamwe maapplication ane zvirambidzo zvakasimba pakukora.

III. Kubudirira kwekugadzira

1) Electroplating tin plating: Maitiro ekugadzira akaomesesa, anoda akati wandei maitiro senge pre-kurapwa, electroplating, uye post-kurapa. Iyo yekumhanyisa yekugadzira inononoka uye haina kukodzera hukuru-hukuru uye hwepamusoro-hunyanzvi kugadzirwa. Nekudaro, kune mamwe madiki-batch uye akagadziridzwa kugadzirwa zvinodiwa, electroplating tin plating ine yakanaka kuchinjika.

2) Kupisa-dip tin plating: Maitiro ekugadzira ari nyore. Iyo tin plating process inogona kupedzwa nekunyudza iyocopper stripmumvura yerata. Iyo yekumhanyisa yekugadzira inokurumidza uye inogona kusangana nezvinodiwa zvehukuru-hukuru kugadzirwa.

IV. Bonding simba:

1) Electroplating tin plating: Iyo yekubatanidza simba pakati pekupfeka uye iyocopper stripsubstrate yakasimba. Izvi zvinodaro nekuti ma tani anoumba zvisungo zvekemikari nemaatomu ari pamusoro pemutsetse wemhangura pasi pekuita kwemunda wemagetsi panguva ye electroplating process, zvichiita kuti kukoira kunetse kudonha5.

2) Kupisa-dip tin plating: Simba rekubatanidza rakanaka zvakare, asi mune dzimwe nguva, nekuda kwekuita kwakaomarara pakati pemvura yerata uye pamusoro pemvura.copper strippanguva yekupisa-dip plating process, mamwe madiki pores kana kuremara anogona kuoneka, achikanganisa kusimba kwekubatanidza. Nekudaro, mushure mekurapa kwakaringana, simba rekubatanidza rekupisa-dip tin plating rinogonawo kusangana nezvinodiwa zveakawanda maapplication.

V. Corrosion resistance:

1) Electroplating tinning: Nekuda kweiyo yakaonda kupfekwa, kusaita ngura kwayo hakuna kusimba. Nekudaro, kana iyo electroplating process yakanyatso kudzorwa uye yakakodzera mushure mekurapa, senge passivation, inoitwa, iyo corrosion resistance yetinned copper stripinogonawo kuvandudzwa

2) Kupisa-dip tinning: Iyo yekupfekedza yakakora, iyo inogona kupa zvirinani kudzivirira kusvibiswa kwekudziviriracopper strip. Mumamiriro ekunze akaomarara, senge hunyoro uye inoora gasi nharaunda, iyo corrosion kuramba mukana wekupisa-dip.tinned copper stripzviri pachena 5.

VI. Mutengo

1) Electroplating tinning: Imari yemidziyo idiki, asi nekuda kwekuoma kwekugadzira maitiro, inoshandisa mamwe magetsi nemakemikari reagents, uye ine zvinodikanwa zvakanyanya kune nharaunda yekugadzira uye vanoshanda, saka mutengo wekugadzira wakakwira.

2) Kupisa-dip tinning: Mari yemidziyo yekudyara yakakura, uye mavira-tembiricha nemimwe michina inoda kuvakwa, asi maitiro ekugadzira ari nyore uye mashandisirwo emidziyo ishoma, saka mutengo weyuniti unogona kunge wakadzikira mukugadzirwa kwakakura.

Kusarudza atinned copper stripyakakodzera kune yako mamiriro ekushandisa inoda kutarisisa kwakadzama kwezvinhu zvakawanda senge magetsi zvivakwa, zvivakwa zvemakanika, corrosion kuramba, maitiro ekugadzira, mutengo uye kuchengetedza kwezvakatipoteredza. Zvinoenderana nezvinodiwa chaizvo, yera zvakanakira nezvayakaipira zvezvinhu zvese uye sarudza iyo yakakodzera kwazvotinned copper stripkuve nechokwadi chekuita uye kunaka kwechigadzirwa.

Nguva yekutumira: Sep-18-2024